Diving bell system

DRASS designs and manufactures different types of diving bells, from 6/6.5 m3 bottom-mating buoyant or sinker, to 8 m3 sidemating sinker diving bells.

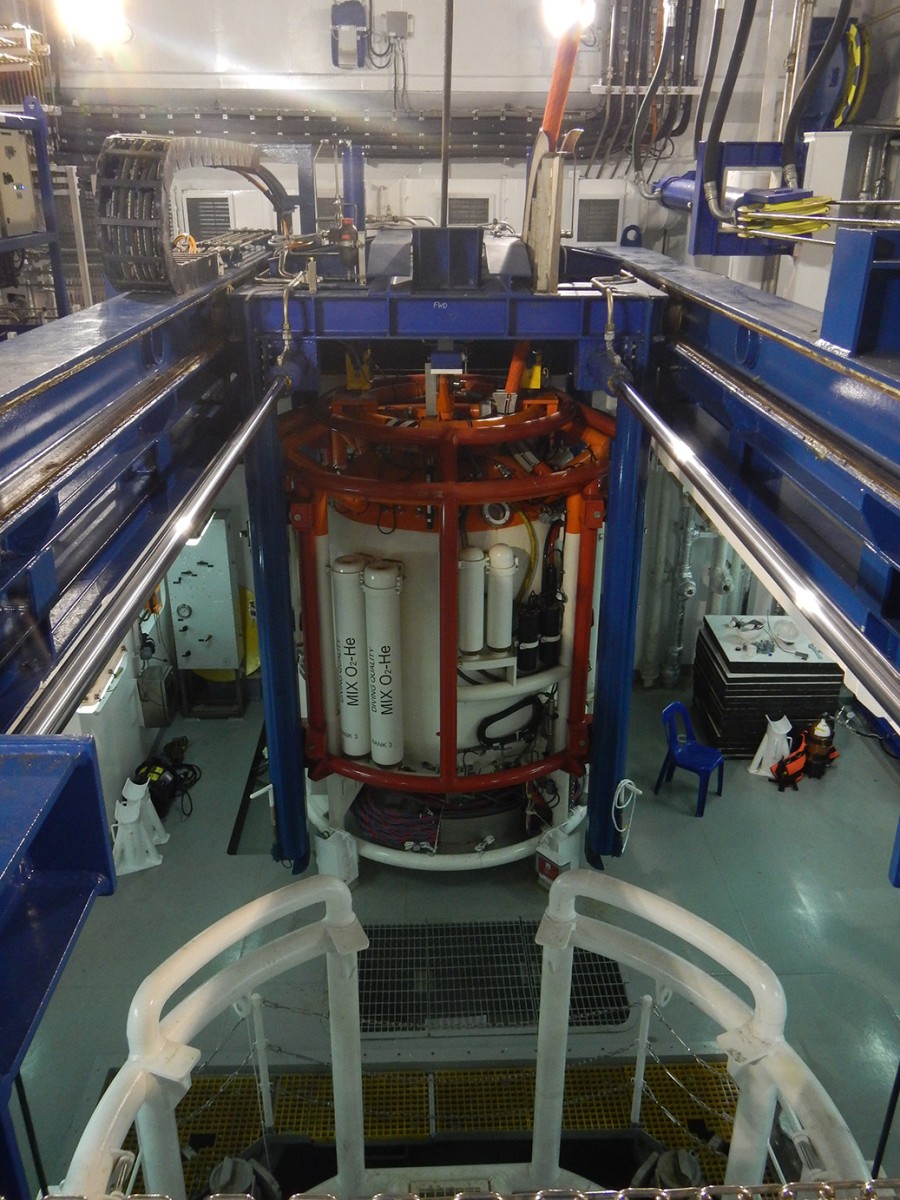

THE DIVING BELL

The traditional Diving Bell is the bottom mating 6 m3 variant successfully certified, delivered, installed, and commissioned on numerous DSVs alongside the standard DRASS 100 Series Saturation Diving System. One significant advantage is the reduced weight of the Diving Bell in air, resulting in minimal stress on the vessel’s superstructure.

Additionally, the buoyancy of the bell renders the diving system independent from the vessel’s crane for tertiary recovery means.

BELL SYSTEM

Designed to operate at depths of up to 300 msw with a design pressure of 31.4 bar, the Diving Bell ensures efficient and reliable performance in challenging underwater environments.

DRASS Bell is designed to comfortably accommodate three divers while ensuring maximum operability. The design ensures optimal comfort and functionality. The bell arrangement, a consolidated design used across various projects, is further validated by simulation studies.

Equipped with new generation DRASS LED lights, the bell provides exceptionally high illumination, surpassing the standards set by NORSOK.

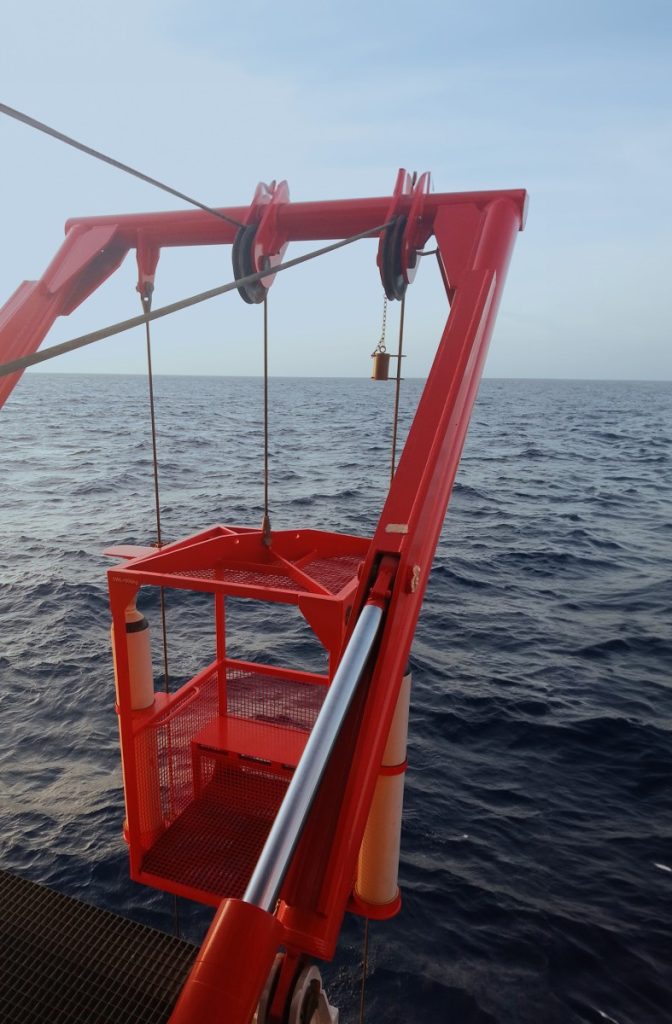

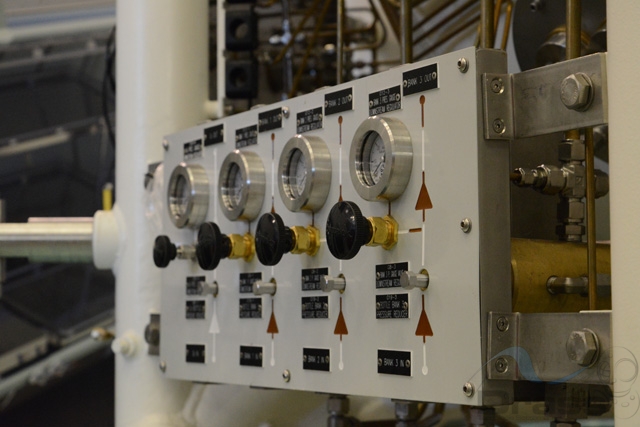

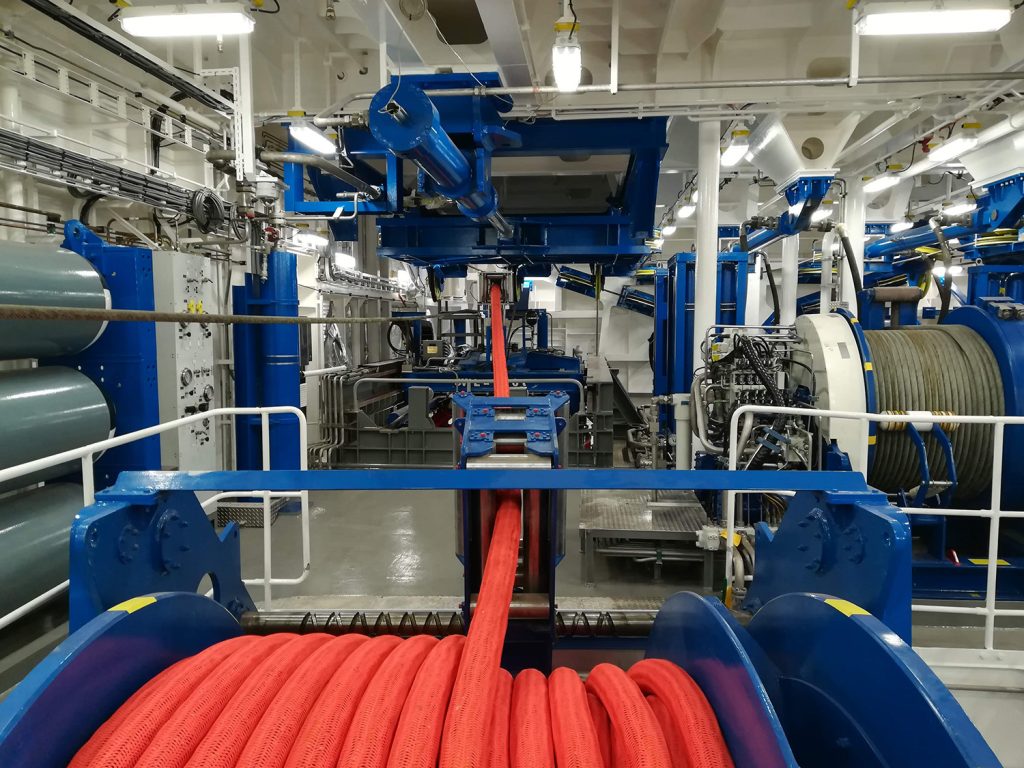

BELL HANDLING SYSTEM

The handling system is a hydraulically activated mechanical setup designed to independently maneuver the diving bell and the clump weight. Both components are fully controlled by the handling control system. This provides hydraulic power to the diving bell’s respective winches and trolley.

AIR DIVE LARS

As counterpart of the 100 Series Saturation Diving System, DRASS offers the Air Diving System, thanks to the LARS (launch and recovery system) as a surface diving setting, benchmark for quality and boasts the most extensive product range available.